Contact Us

Telephone:+8615992545097

Add:Guanxiyang Road,east of Tianfu Road,Xinan Office, Konggang Economic Zone,Jieyang City,Guangdong Province

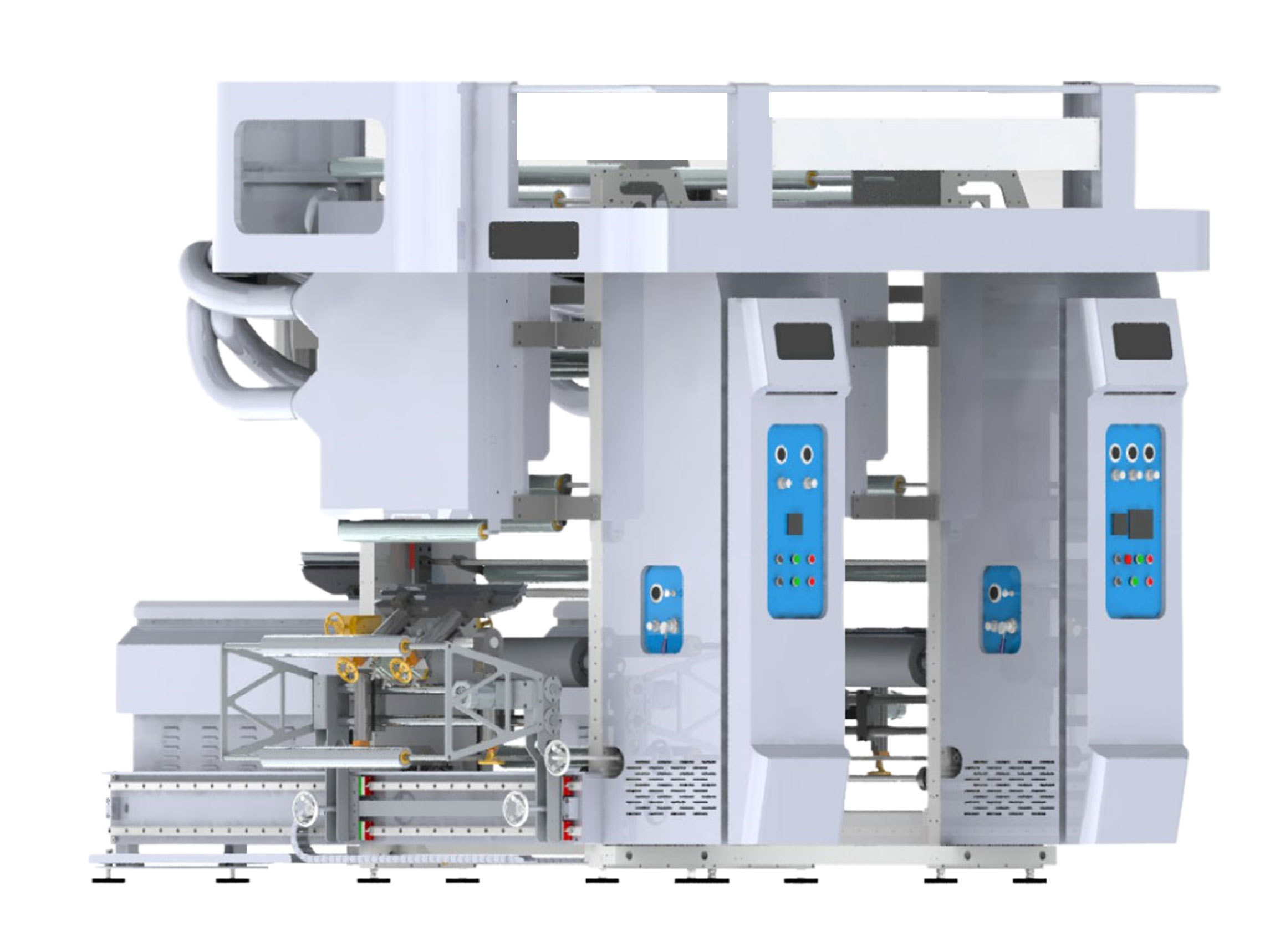

3.Electronic shaft unit type rotogravure printing machine,

1.The central impression ( central drum ) flexographic printing machine

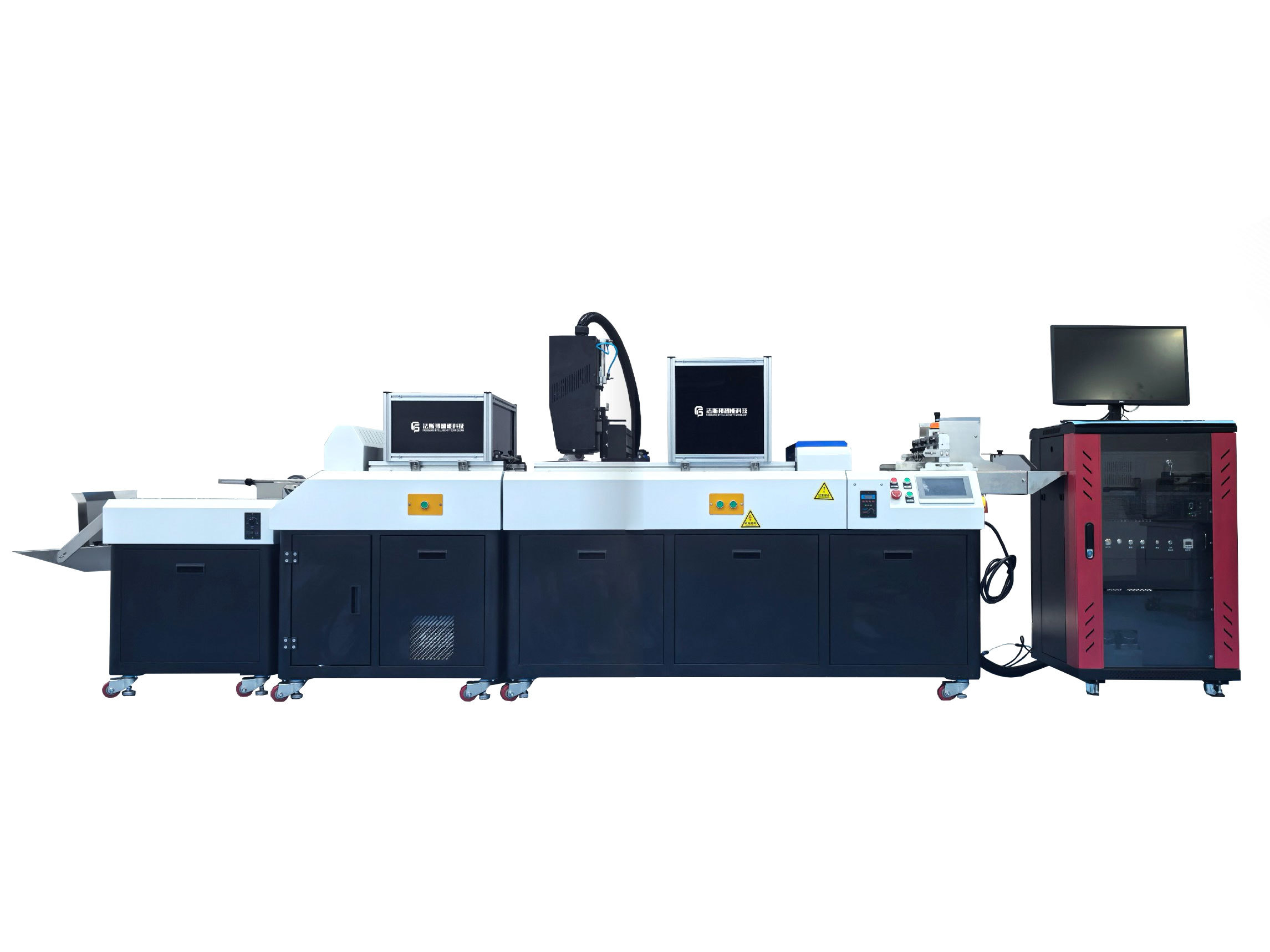

Electronic shaft fsb800 water-based ink rotogravure printing machine

Standard Electronic Shaft High Speed Plastic Bag Rotogravure Printing Press

Electronic shaft unit type rotogravure printing machine,

The central impression ( central drum ) flexographic printing machine

High-speed fully automatic electronic shaft-connected printing machine